From the beginning of 2025, Thong Nhat Coal Company issued Plan No. 651/KH-VTNC, with the goal of promoting the application of mechanization, automation, and digital transformation in production and management to improve working conditions for workers, increase labor productivity, with special attention to the electromechanical - transportation sector.

Recently, the Company organized the installation of a signboard for the project of connecting two slope conveyor lines 7A and 7B into one main shaft conveyor line (+41/-140). The project was implemented by the Mechanical and Electrical - Transportation Department in coordination with related departments under the direction of the Kiln Transport Workshop 1, bringing high efficiency in reducing operating labor costs and electricity consumption costs. At the same time, it created favorable conditions for the repair and maintenance of the main conveyor line, increasing the continuous and stable transportation capacity for the company's production.

The unit also organized training and put into use the Electromechanical - Transportation Management software, with the aim of managing and standardizing information on assets, machinery and equipment, materials for replacement, repair and maintenance, records, monitoring forms and technical parameters that need to be managed... The digital management system helps ensure that all data on assets, machinery and equipment are managed throughout the life cycle from investment, purchase, exploitation, operation and depreciation to asset liquidation to serve as a database for digitization and standardization of data according to TKV's digital transformation orientation. In addition, in 2025, the Company also signed a training cooperation agreement with Kushiro Coal Company (Japan), including content on management and maintenance techniques related to rails.

According to comrade Nguyen Manh Toan, Party Secretary, Director of Thong Nhat Coal Company, in the period of 2025-2030, the Company will continue to promote production and business, initially successfully implementing the plan of raw coal output of 2 million tons in 2025; in the following years, striving for a revenue growth rate of 3-5%/year; reducing work accidents, striving for no serious accidents and incidents. Strengthening the management of electromechanical and transportation in production is important to improve safety and production efficiency. In particular, controlling electricity targets and reducing costs helps the unit have more resources to focus on investing in equipment to improve the capacity of backup power supply, drainage pumps, equipment for transporting people, materials and equipment.

The Mechanical and Electrical - Transport Department (TKV) said that currently, the number of mines with installed passenger transport equipment is 246 systems; the total number of equipment invested and installed to serve the transportation of materials and equipment is about 2,347 sets. There are 14 synchronized mechanized lines for longwall coal mining being used at 10/13 units, with the capacity of the line ranging from 300,000 - 1.2 million tons. tons/year; 16 CGH lines digging coal tunnels with Combai EBH45 machines... Basically, CGH lines, semi-CGH mining and tunneling equipment have been invested and put into stable operation, reaching the designed productivity, increasing efficiency and improving working conditions for workers. The underground units are managing and operating 40 main pumping stations (central pumping stations) and auxiliary pumping stations with large drainage capacity to serve the drainage pumping and incident response of 13 underground units...

Mr. Nguyen Van Tuan, Deputy General Director of TKV, said: The Group requires units to continue to strictly comply with the operating discipline and direction of TKV, resolutely implement and complete plans and tasks; coordinate with the Electricity sector to resolve problems in power supply, ensure production service, incident response, storm prevention; focus on reviewing, inspecting, testing, implementing maintenance and repair regimes for electromechanical and transportation equipment, ensuring stable operation of equipment, especially the backup generator system. At the same time, review and supplement regulations on equipment operation; strengthen inspection and supervision of workers in implementing procedures, standards, and safety measures in operating and using equipment; continue to implement the Group's direction on the transportation of people and equipment in the furnace according to regulations; promote mechanization, automation, and digital transformation in production and management related to the electromechanical - transportation sector; Carry out major repairs and overhauls of equipment according to plan; complete mechanical and electrical works - transportation well to meet TKV's production needs.

Source: https://baoquangninh.vn/quan-ly-co-dien-van-tai-dap-ung-yeu-cau-san-xuat-than-3369910.html

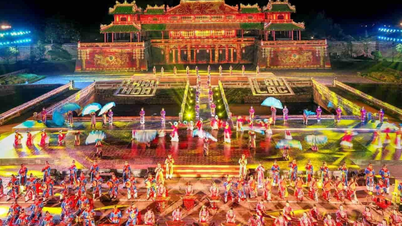

![[Photo] Nghe An: Provincial Road 543D seriously eroded due to floods](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/5/5759d3837c26428799f6d929fa274493)

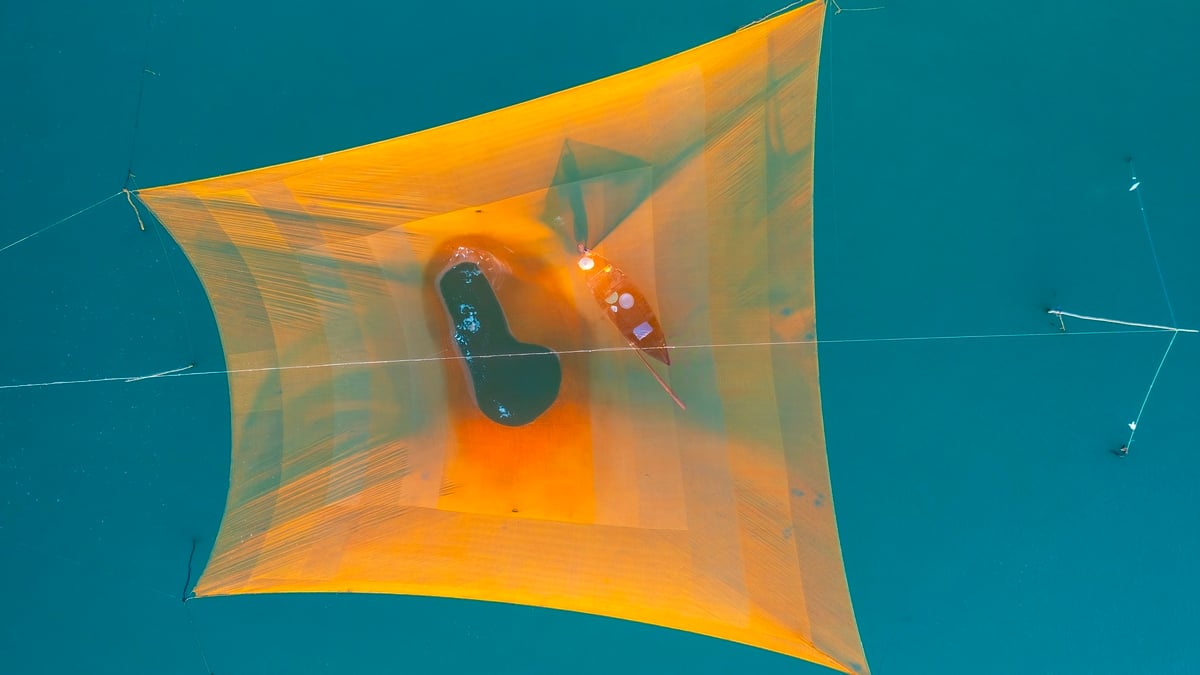

![[Photo] Discover the "wonder" under the sea of Gia Lai](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/6/befd4a58bb1245419e86ebe353525f97)

Comment (0)